|

|

|

|

|

|

|

|

| Tapes for Insulation |

|

Product Information |

| Product |

Structure

(Material

/Adhesive ) |

Heat resistance

(°C) |

Product

Thickness

(mils)/

(mm) |

Dielectric Strength

(V) |

Insulation Resistance

(mega-

ohms) |

Tensile force

(lb/in)/

(N/10 mm) |

percent elongation

(%) |

Illuminations factor

(How 3M) |

Adhesion

(oz/in)/

(N/10 mm) |

File UL

Standard

E17385 |

| Glass Cloth |

| 27 |

Glass Cloth/

RT |

150 |

7.0/0,177 |

3000 |

4.8x1044 |

150/252 |

5 |

0.9 |

30/3,3 |

UL 510 |

| 79 |

Glass Cloth/

Acrylic |

150 |

7.0/0.177 |

3000 |

2.7x102 |

150/262 |

5 |

0.9 |

30/3.3 |

UL 510 |

| 69 |

Glass Cloth/

Silicone |

200 |

7.0/0.177 |

3000 |

4.8x104 |

180/314 |

5 |

0.9 |

40/4.4 |

UL 510FR |

| Product |

Structure

(Material

/Adhesive ) |

Heat resistance

(°C) |

Product

Thickness

(mils)/

(mm) |

Dielectric Strength

(V) |

Insulation Resistance

(mega-

ohms) |

Tensile force

(lb/in)/

(N/10 mm) |

percent elongation

(%) |

Illuminations factor

(How 3M) |

Adhesion

(oz/in)/

(N/10 mm) |

File UL

Standard

E17385 |

| Filament Reinforced |

| 46 |

PET+Glass filaments/RT |

130 |

7.0/0.177 |

5500 |

3x103 |

275/481 |

5 |

1.0 |

50/5,4 |

UL 510 |

| 1146 |

PET+Glass filaments |

130 |

7.0/0.177 |

5500 |

- |

300/525 |

5 |

- |

300/525 |

|

| 1139 |

PET/Glass filaments |

155 |

6.5/0,165 |

5500 |

- |

225/394 |

6 |

- |

35/3,8 |

UL 510 |

| 1276 |

Paper+Glass filaments/RT |

105 |

9.0/0,228 |

3500 |

- |

275/481 |

5 |

1.0 |

40/4,4 |

UL 510 |

| 1339 |

PET+Glass filaments/Acrylic |

130 |

6.5/0,165 |

5500 |

1x105 |

275/481 |

5 |

1.0 |

35/3,8 |

UL 510 |

| Product |

Structure

(Material

/Adhesive ) |

Heat resistance

(°C) |

Product

Thickness

(mils)/

(mm) |

Dielectric Strength

(V) |

Insulation Resistance

(mega-

ohms) |

Tensile force

(lb/in)/

(N/10 mm) |

percent elongation

(%) |

Illuminations factor

(How 3M) |

Adhesion

(oz/in)/

(N/10 mm) |

File UL

Standard

E17385 |

| Acetate Cloth |

| 11 |

Black acetate/RT |

105 |

7.0/0,178 |

2000 |

2x104 |

35/62 |

10 |

1 |

40/4,4 |

- |

| 28 |

White acetate/RT |

105 |

8.0/0,203 |

2500 |

2x104 |

40/70 |

10 |

1 |

40/4,4 |

- |

| Product |

Structure

(Material

/Adhesive ) |

Heat resistance

(°C) |

Product

Thickness

(mils)/

(mm) |

Dielectric Strength

(V) |

Insulation Resistance

(mega-

ohms) |

Tensile force

(lb/in)/

(N/10 mm) |

percent elongation

(%) |

Illuminations factor

(How 3M) |

Adhesion (oz/in)/

(N/10 mm) |

File UL

Standard

E17385 |

| Composite Film |

| 44 |

PET Matt Film/

RT |

130 |

5.5/0,139 |

5500 |

>1x106 |

40/70 |

50 |

1.0 |

65/7,1 |

UL 510 |

| 44HT |

PET Matt Film/

RT |

130 |

5.5/0,139 |

5500 |

>1x106 |

40/70 |

50 |

1.0 |

80/8,8 |

UL 510 |

| 55 |

PET Matt Film/

RT |

130 |

7.5/0,190 |

6000 |

>1x106 |

35/62 |

30 |

1.0 |

80/8,8 |

UL 510 |

| 44D-A |

PET Matt Film/

RT |

130 |

12/0,304 |

6000 |

>1x106 |

40/70 |

20 |

1.0 |

35/3,8 |

UL 510 |

| 44T-A |

PET Matt Film/

RT |

130 |

18/0,455 |

8500 |

>1x106 |

80/141 |

20 |

1.0 |

45/4,9 |

UL 510 |

| Product |

Structure

(Material

/Adhesive ) |

Heat resistance

(°C) |

Product

Thickness

(mils)/

(mm) |

Dielectric Strength

(V) |

Insulation Resistance

(mega-

ohms) |

Tensile force

(lb/in)/

(N/10 mm) |

percent elongation

(%) |

Illuminations factor

(How 3M) |

Adhesion (oz/in)/

(N/10 mm) |

File UL

Standard

E17385 |

| Epoxy Film |

| 1 |

Epoxy Film/RT |

130 |

3.5/0,088 |

6500 |

>1x106 |

30/53 |

120 |

1.0 |

40/4.4 |

UL 510FR |

| Super 20 |

Epoxy Film/RT |

155 |

5.0/0,127 |

8000 |

>1x106 |

45/79 |

120 |

1.0 |

30/3.3 |

UL 510FR |

| Super 10 |

Epoxy Film/RT |

155 |

5.0/0,127 |

8000 |

>1x106 |

45/79 |

120 |

1.0 |

45/4.9 |

UL 510FR |

| Product |

Structure

(Material

/Adhesive ) |

Heat resistance

(°C) |

Product

Thickness

(mils)/

(mm) |

Dielectric Strength

(V) |

Insulation Resistance

(mega-

ohms) |

Tensile force

(lb/in)/

(N/10 mm) |

percent elongation

(%) |

Illuminations factor

(How 3M) |

Adhesion

(oz/in)/

(N/10 mm) |

File UL

Standard

E17385 |

| paper |

| 12 |

If the plane/RT |

105 |

5.5/0.14 |

2000 |

>1x106 |

22/38,5 |

- |

- |

40/4.4 |

- |

| 16 |

Crepe paper/RT |

105 |

9.0/0.228 |

2500 |

>1x106 |

25/44 |

10 |

- |

50/5.5 |

- |

| Product |

Structure

(Material

/Adhesive ) |

Heat resistance

(°C) |

Product

Thickness

(mils)/

(mm) |

Dielectric Strength

(V) |

Insulation Resistance

(mega-

ohms) |

Tensile force

(lb/in)/

(N/10 mm) |

percent elongation

(%) |

Illuminations factor

(How 3M) |

Adhesion (oz/in)/

(N/10 mm) |

File UL

Standard

E17385 |

| Polyester Film |

| 5 |

PET Film/Acrylic |

130 |

2.5/0,063 |

5500 |

>1x106 |

25/44 |

100 |

1.0 |

35/3.8 |

UL 510 |

| 1318-1 |

PET Film/Acrylic |

130 |

2.5/0,063 |

5500 |

>1x106 |

25/44 |

100 |

1.0 |

30/3.3 |

UL 510 |

| 1350F-1 |

PET Film/Acrylic |

130 |

2.5/0,063 |

5500 |

>1x106 |

25/44 |

100 |

1.0 |

30/3.3 |

UL 510 |

| 1350F-2 |

PET Film/Acrylic |

130 |

3.3/0,083 |

7000 |

>1x106 |

50/88 |

100 |

1.0 |

30/3.3 |

UL 510 |

| 1351-1 |

PET Film/Acrylic |

130 |

2.5/0,063 |

5500 |

>1x106 |

25/44 |

100 |

1.0 |

30/3.3 |

UL 510 |

| 54 |

PET Film/RT |

130 |

2.5/0,063 |

5500 |

>1x106 |

25/44 |

100 |

1.0 |

45/4.9 |

UL 510 |

| 56 |

PET Film/RT |

130 |

2.5/0,063 |

5500 |

>1x106 |

25/44 |

100 |

1.0 |

50/5.5 |

UL 510 |

| 57 |

PET Film/RT |

130 |

3.3/0,083 |

7000 |

>1x106 |

50/88 |

100 |

1.0 |

60/6.5 |

UL 510 |

| 58 |

PET Film/RT |

130 |

3.3/0,083 |

7000 |

>1x106 |

50/88 |

100 |

1.0 |

60/6.5 |

UL 510 |

| 74 |

PET Film/RT |

130 |

0.8/0,020 |

3500 |

>1x106 |

12/21 |

100 |

1.0 |

20/2.2 |

UL 510 |

| 75 |

PET Film/RT |

130 |

3.8/0,096 |

6500 |

>1x106 |

25/44 |

100 |

1.0 |

45/4.9 |

UL 510 |

| Product |

Structure

(Material

/Adhesive ) |

Heat resistance

(°C) |

Product

Thickness

(mils)/

(mm) |

Dielectric Strength

(V) |

Insulation Resistance

(mega-

ohms) |

Tensile force

(lb/in)/

(N/10 mm) |

percent elongation

(%) |

Illuminations factor

(How 3M) |

Adhesion (oz/in)/

(N/10 mm) |

File UL

Standard

E17385 |

| Polyimide Film |

| 92 |

Polyimide Film/Silicone |

180 |

3.0/0,076 |

7500 |

>1x106 |

30/53 |

55 |

1.0 |

25/2.8 |

UL 510FR |

| 1093 |

Polyimide Film/Silicone |

180 |

2.5/0.063 |

7500 |

>1x106 |

35/62 |

50 |

- |

20/2.2 |

UL 510FR |

| 92-2 |

Polyimide Film/Silicone |

180 |

3.5/0.089 |

10000 |

>1x106 |

60/105 |

55 |

- |

25/2.8 |

UL 510FR |

| 1205 |

Polyimide Film/Acrylic |

155 |

3.0/0,076 |

7500 |

>1x106 |

30/53 |

55 |

1.0 |

35/3.8 |

UL 510FR |

| 1218 |

Polyimide Film/Acrylic |

180 |

3.0/0,076 |

6000 |

>1x106 |

30/53 |

55 |

1.0 |

19/2.1 |

UL 510FR |

| Product |

Structure

(Material

/Adhesive ) |

Heat resistance

(°C) |

Product

Thickness

(mils)/

(mm) |

Dielectric Strength

(V) |

Insulation Resistance

(mega-

ohms) |

Tensile force

(lb/in)/

(N/10 mm) |

percent elongation

(%) |

Illuminations factor

(How 3M) |

Adhesion (oz/in)/

(N/10 mm) |

File UL

Standard

E17385 |

| PTFE Film |

| 60 |

PTFE Film/

Silicone |

180 |

4.0/0,102 |

9500 |

>1x106 |

20/35 |

200 |

1.0 |

30/3.2 |

UL 510FR |

| 61 |

PTFE Film/

Silicone |

180 |

7.0/0,178 |

15000 |

>1x106 |

45/79 |

200 |

1.0 |

35/3.8 |

UL 510FR |

| 62 |

PTFE Film/

Silicone |

180 |

4.0/0,102 |

9500 |

>1x106 |

20/35 |

200 |

1.0 |

30/3.2 |

UL 510FR |

| 63 |

PTFE Film/

Acrylic |

155 |

3.5/0,088 |

9500 |

>1x106 |

20/35 |

200 |

1.0 |

35/3.8 |

UL 510FR |

♦Note: the documents stated above are normal documents, they can not be used for business purposes, it must check the usage purposes before deciding to use

•Kind of Adhesive

·RT-Rubber thermosetting adhesive

·ST-Thermosetting silicone adhesive

·Acrylic-The acrylic pressure sensitive adhesive |

| Product |

Structure

(Material

/Adhesive ) |

Heat resistance

(°C) |

Product

Thickness

(mils)/

(mm) |

Dielectric Strength

(V) |

Insulation Resistance

(mega-

ohms) |

Tensile force

(lb/in)/

(N/10 mm) |

percent elongation

(%) |

Illuminations factor

(How 3M) |

Adhesion (oz/in)/

(N/10 mm) |

File UL

Standard

E129200 |

| Vinyl |

Scotch®

22 |

PVC/Rubber |

80 |

10.0/0,254 |

12000 |

>1x106 |

20/35 |

200 |

1.0 |

25/2.7 |

UL 510 |

Scotch®

33 |

PVC/Rubber |

80 |

7.0/0,177 |

7000 |

>1x106 |

17/30 |

200 |

1.0 |

24/2.6 |

UL 510 |

Scotch®

Super

33+ |

PVC/Rubber |

105 |

7.0/0,177 |

8750 |

>1x106 |

15/26 |

250 |

- |

28/3.0 |

UL 510 |

Scotch®

35 |

PVC/Rubber |

105 |

7.0/0,177 |

8750 |

>1x106 |

17/30 |

225 |

- |

20/2.2 |

UL 510 |

Scotch®

super

88 |

PVC/Rubber |

105 |

8.5/0,215 |

1000 |

>1x106 |

20/35 |

250 |

- |

25/2.7 |

UL 510 |

3M™

Tartan™

1710 |

PVC/Rubber |

80 |

7.0/0,177 |

7500 |

>1x106 |

17/30 |

200 |

- |

18/1.9 |

UL 510 |

3M™

Temflex™

1700 |

PVC/Rubber |

80 |

7.0/0,177 |

7000 |

>1x106 |

17/30 |

200 |

- |

24/2.6 |

UL 510 |

| Product |

Tape |

Feature |

Thickness |

ProductionStandard |

Temperature

range

(℃) |

|

| Electrical Tape |

Scotch®

13 |

|

•Semi-conductive rubber Tapes |

0.76mm |

19mm X 4.5M |

Long-term 90℃

Short term 130℃ |

For high pressure. Cable insulation shield |

Scotch®

22 |

|

Vinyl Tapes

for electrical insulation

& bull; Mechanical Strength The Great

•UL Listed CSA cetified |

0.25mm |

35mm X 33M

38mm X 33M |

Long-term 80℃ |

Reinforced insulation busbar

Cable sheath repair |

Scotch®

23 |

|

•Self sealable rubber Tapes

& bull; Available until proof .69KV |

0.76mm |

19mm X 4.5M

19mm X 9M |

Long-term 90℃

Short term 80℃ |

Cable insulation for high pressure |

Scotch®

24 |

|

•Shielding Tapes

& bull; temperature stability |

|

25mm X 4.5M |

|

A straight line connecting the shield layer connection |

Scotch®

25 |

|

•Ground Tapes

& bull; conductivity is excellent |

|

13mm X 1.5M |

|

For a straight line connecting terminal and ground |

Scotch®

Super 33+ |

|

•Taeyipeu plastic for electrical insulation

& bull; work in low temperature (-18 ℃) & nbsp;

& bull; deformation caused by ambient temperature None, |

0.18mm |

19mm X 10M

19mm X 20M

50mm X 10M |

105℃ |

Wires connected to 1000V

High-voltage cables and forming |

Scotch®

35 |

|

•Taeyipeu plastic for electrical insulation

& bull; can work even at low temperature (-18 ℃)

& bull; deformation caused by ambient temperature None, |

0.18mm |

19mm X 20M |

105℃ |

Wires connected to 1000V

High-voltage cables and forming

9 colors |

Scotch®

50 |

|

•Tapes corrosion-proof |

0.25mm |

50mm X 30M |

80℃ |

Corrosion protection, such as a pipe or pipe |

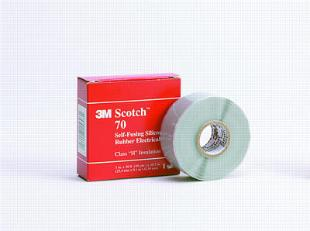

Scotch®

70 |

|

•Silicone Rubber Tapes

& bull;. self-sealable strong weather resistance |

0.3mm |

25mm X 9M |

180℃ |

High-voltage cable terminal treatment waterproof and reinforced insulation |

Scotch®

77 |

|

•Fire-resistant and arc resistant Tapes

& bull;

as a non-self-extinguishing plastic material

& bull; excellent flexibility |

0.76mm |

75mm X 6M |

|

Fire-resistant and arc resistant

Fire insulation firewall role |

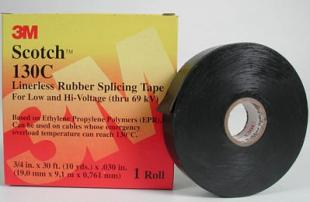

Scotch®

130C |

|

•Self sealable rubber Tapes

& bull; Available until proof .69KV |

0.76mm |

19mm X 9M

50mm X 9M |

Long-term 90℃

Short term 130℃ |

Cable insulation for high pressure |

Temflex

1610 |

|

•Electrical Tapes for Insulation

& bull; A variation of the ambient temperature to None |

0.15mm |

19mm X 20M |

80℃ |

Available up to 1000V |

Temflex

1711 |

|

•Electric Tapes for Insulation

•A variation of the ambient temperature in None |

0.18mm |

19mm X 10M |

80℃ |

Available up to 1000V |

Scotch®

2200 PAD |

|

•Electric Insulation moisture-proof pad

•Self-sealable |

3.17mm |

114mm X 165mm |

80℃ |

Moisture and insulation

And the uneven surface of the adhesive also easy |

Scotch®

2228 |

|

•Electric Moisture-proof insulatingTapes

•Self-sealable |

1.65mm |

50mm X 3M |

Long-term 90℃

Short term 130℃ |

ElectricInsulated bus bar insulation

Straight connection Connection |

Scotchfil

Putty |

|

•Electric Moisture-proof insulatingPutty

•Self-sealable.Excellent dielectric strength |

3.17mm |

38mm X1.5M |

80℃ |

Components are connected directly with low pressure and moisture resistance. |

|

|